PAT Testing

Why PAT Test? Pat testing is a routine inspection of many different types of electrical appliance or extension lead to check they are safe to use. The purpose is to prevent electrical shocks or incidents at your workplace.

How often should I PAT test? Well this really depends on what the equipment is and where and when it is used. As a general rule the maximum amount of time between tests should be 12 months but we may advise some items are tested more frequently – this particularly applies to items used in an industrial environment where the chances of damage etc are much higher.

Is PAT testing disruptive to my workplace? We try to cause as little disruption as possible to your site and will work round you as much as possible including working out of hours if needed.

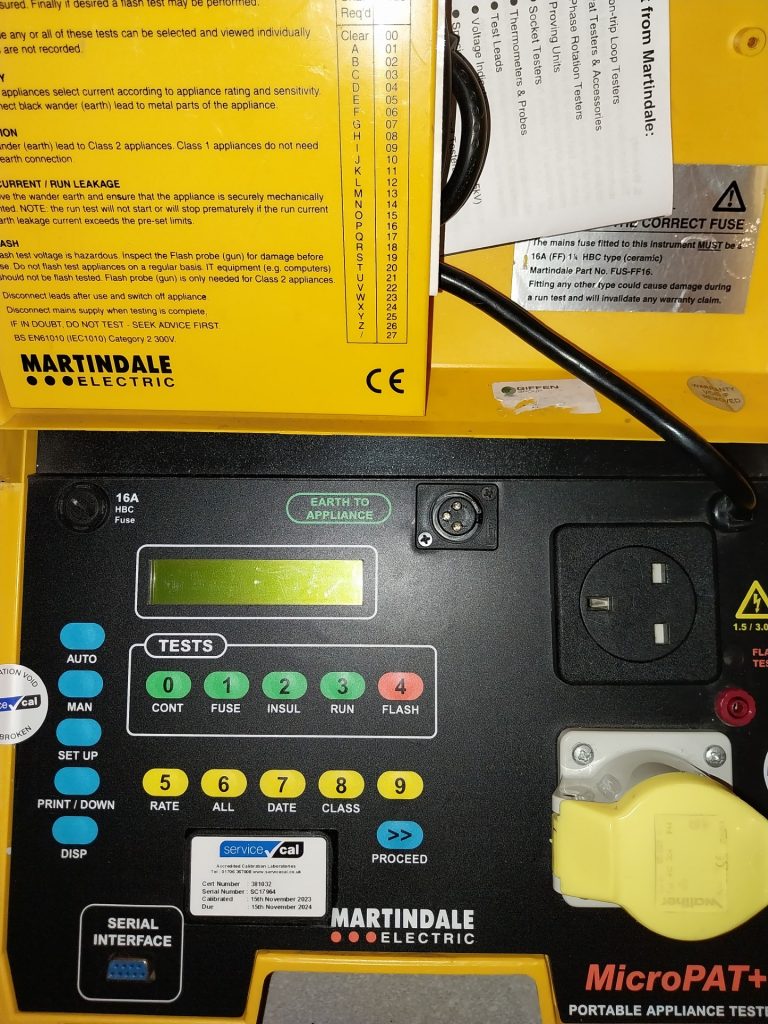

How long does PAT testing take? We only need each item for a short period of time. We will carry out a full visual test of the appliance or lead etc and then test the item using our calibrated test equipment. This usually only takes a few minutes per item. The total amount of time we will be on site will depend on how many items you have and where and how they are located – its much quicker to test if they are all together ready in one place when we arrive but we know that often isn’t possible.

Will I get a record of the items you have tested? Yes of course. We will put a sticker on every item when we have tested it. We will also note down the results of every item as we test them and will send you on a full report of every item we have tested and the results we from those tests so you have a full record.

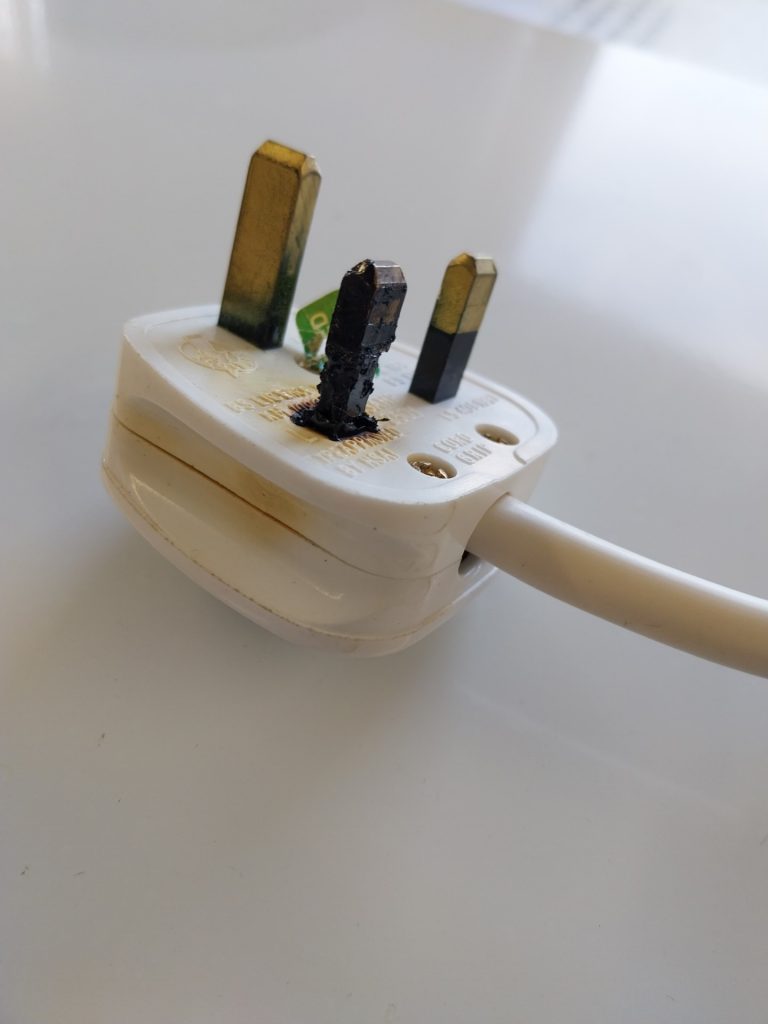

Why use us for your PAT testing? We are qualified electricians so we will visually inspect all of your items fully, when we test your items we can interpret the results not just as a pass/fail but we understand what the values mean (you would be surprised how many PAT testers just plug it in and just accept a result from the meter without understanding the results) and whether there may be an underlying issue or in the event of a fail we may be able to carry out necessary repairs to get the item a pass. We also check simple thing like the tightness of connections in plugs, fuse size and whether this is correct for the appliance – does your current PAT tester do these checks?

Our PAT testing equipment is fully service, tested and calibrated by an external company annually with full test certificate provided to us so you can be sure all the equipment we are using is fully compliant and correct

Recent work